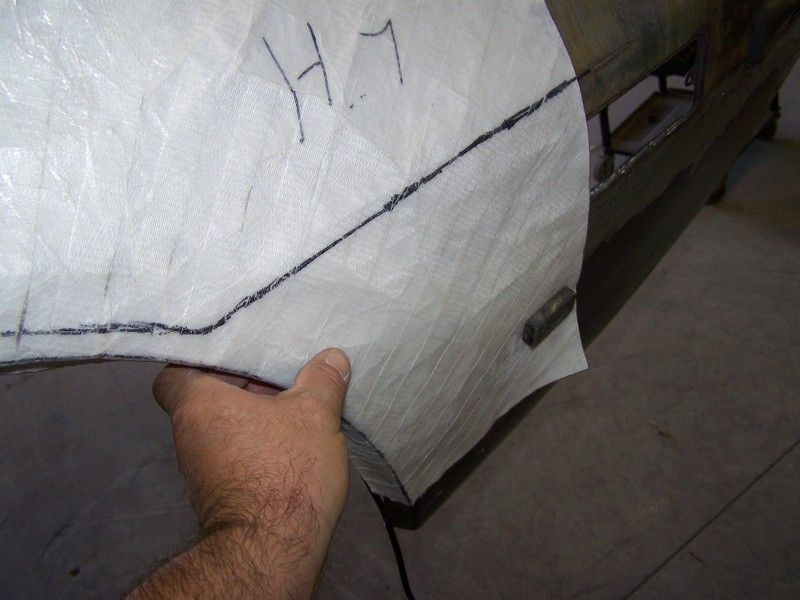

My welding skills are getting better Trunk Pan is welded up on both sides on the frame rails now and all across the front on the rear most seam still have the front seam to do Then I can start on the Trunk drop offs I will get to that this next weekend when I have more time off.

What a pain to get in that trunk killing my back my weight & size doesn't help much!

But To me seams like I'm on down hill side.

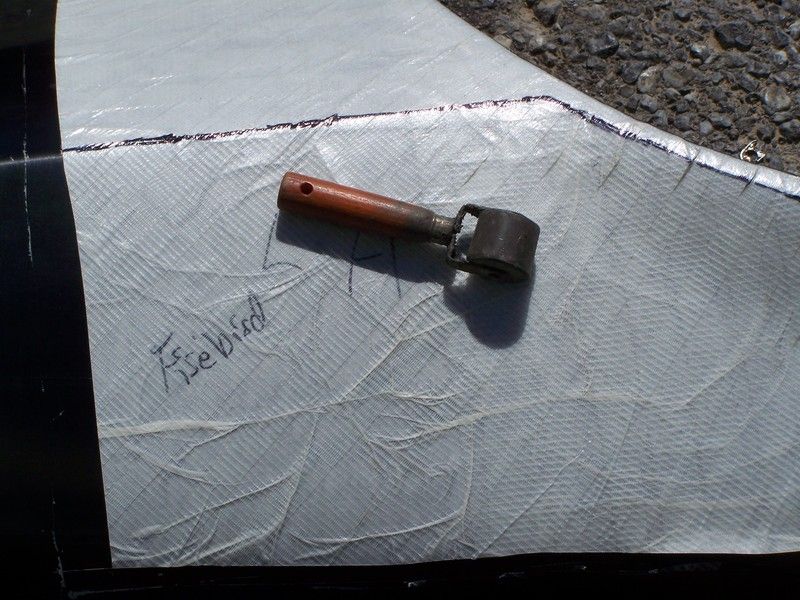

I ended up using the Tig for 99% of it and I have to admit to using my Mig for some of the welds just not possible to get into some of those areas with the Tig with both arms stretched out no way to see so I had to break down and whip out the mig sure is easy doing plug weld with a Mig lots easyer than Tig. But the Tig produces a Better weld with less heat. still have a lot of clean up to do too grinding stuff down. need to find my camera cord so I can down load pics.

TOO LOUD!!! TOO BRIGHT!!! TOO TIGHT!!! TOO FAST!!!

32 posts

• Page 4 of 4 • 1, 2, 3, 4

|

Top Contributor

Posts: 6233

Joined: Tue Sep 16, 2008 1:17 pm Location: Pahrump NV. Country: USA |

Dennis B.

A&P Mechanic, FCC General radio Telephone Operator Line Maintenance A&P Mechanic and MOC Tech specialist. |

32 posts

• Page 4 of 4 • 1, 2, 3, 4

Who is online

Users browsing this forum: No registered users and 26 guests