If I have a crack some where can I drill a hole at the end of the crack then repair with adhesive? Or is it better to cut the whole area out?[im

Fully Engaged

Posts: 327

Joined: Thu Jan 12, 2006 9:09 pm Location: Plainfield, IL |

I cut the high area out then removed material from the loose piece to make it smaller as needed. Then held the loose piece in place with Duck tape as suggested-Worked great! I used a little SMC adhesive in the joints to hold it in place. Then took off the fender and used 4 strips off cloth plus adhesive on back side of the seam. On the top side I chopped up mat in fine pieces and applied. The final coat on the top was only Adhesive. I drilled a 1/4" hole at the intersection of the cuts-OK??

If I have a crack some where can I drill a hole at the end of the crack then repair with adhesive? Or is it better to cut the whole area out?[im   "The smoker you play is the drinker you get"

|

Fully Engaged

Posts: 327

Joined: Thu Jan 12, 2006 9:09 pm Location: Plainfield, IL |

Can I use High build epoxy Primer on the SMC?

"The smoker you play is the drinker you get"

|

|

Okay, looking good, fender to door gaps are starting to take on a production look. Idea of stress relieveing a crack by drilling is debated a lot on paint and body forums. The idea is to stop the crack from spreading out. Sure can't hurt. I do still cut some areas out though depending on what I'm seeing (thin spots, areas prone to hitting, vibration, etc.).

High build epoxy primer on SMC, sure should be no problem as long as it is a true epoxy product. You might want to double check your P sheet on the stuff just to make sure it says SMC compatible. Almost all ( I'm sure there are some exceptions to this somewhere) epoxy products will stick to SMC. Hey, this is really starting to look good. Can't wait to see it done. Metal, wood, fiberglass, we work it all... www.furniturephysicians.com We can restore the irreplaceable!

|

|

Fully Engaged

Posts: 327

Joined: Thu Jan 12, 2006 9:09 pm Location: Plainfield, IL |

[img

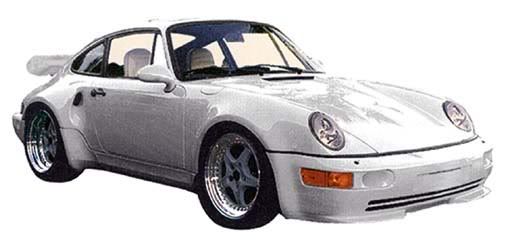

A pic of Saturday's project. Going to ruin a perfect quarter panel and it kinda hurts. Cutting the quarter panel and adding the flare. Initial inspection tells me the SMC doesn't fit very well.[i   "The smoker you play is the drinker you get"

|

|

That fender flare looks like a lot of fun.

Metal, wood, fiberglass, we work it all... www.furniturephysicians.com We can restore the irreplaceable!

|

|

Fully Engaged

Posts: 327

Joined: Thu Jan 12, 2006 9:09 pm Location: Plainfield, IL |

Does not have to look that smooth. They tell me the Hoosier tires throw rocks all over the car and chip it up anyway. I went to Road America last weekend and the paint jobs were pretty cool.(bright) I want to have fun with a cool color and Try something harder. Only shot solid Base colors up to now. Would like to try a Pearl or KBC. Maybe HOK Burple or Tangelo? Any idea's? Try'ed Silver and had some stripes--Tricky!!! I was going to bond the flare with Fusor T21? What do you think? What do you mean guide coat the mating surface?

"The smoker you play is the drinker you get"

|

|

If you're not concerned that much about the smoothness of the transition then I guess the guide coating is really not needed. Some tips on color here... If you're having problems with striping on silver you're probably going to have a real bad time with the colors you mentioned. Why don't you think about doing a color transition from a solid on the bottom to a faded metallic so fixing those color chips will be simple in the future. Solid colors lower is a much better idea keeping those bright colors up top. I do this on my show cars so I can easily fix any chips hits on the lower portion of the car. It's almost impossible to spot in those metallic or pearl effects in chips. Fusor is fine for the bonding.

Metal, wood, fiberglass, we work it all... www.furniturephysicians.com We can restore the irreplaceable!

|

|

Fully Engaged

Posts: 327

Joined: Thu Jan 12, 2006 9:09 pm Location: Plainfield, IL |

I want to do the best job I can!!(want it to look like the pic) How would you go about mounting those flares??? Guide coat do you mean: Spraying a coat of another color and sanding it off to check for low and high spots? An advantage I have noticed working with SMC and adhesive filler is that everything sands at the same rate vs. Steel panels and polyester filler. Thamks for your help!!!!!!!! Tommorrow is D=day for the quarters.

"The smoker you play is the drinker you get"

|

|

Sorry I didn't get back to you sooner on this but I've been on the road a lot in the last two weeks.

First, did you get any kind of mounting instructions with those things? What I am getting at is, are they mostly a "cap-over" style fender flare or do you actually cut and remove some of the existing fender? If there is any type of body cavity formed by a cap-over style make sure to put some drain or weep holes in the bottom. Combo SMC and metal hollow areas generate moisture that can rust at your blend/attachment points. As for the guide coating. I'll guarantee you they guide coated the hell out of the white Porsche in the pic. Yes, it's just a matter of using a contrasting color (usually black) spray can and dusting or speckling it on over the area. I prefer powdered guide coat (Evercoat) because it shows up every mintue detail of the contours. High spots will sheer off and low spots will still have the guide coat on them. Trust me you'll see every wave, ripple and defect that you'll need to address if you want it looking like that white car. Metal, wood, fiberglass, we work it all... www.furniturephysicians.com We can restore the irreplaceable!

|

|

Fully Engaged

Posts: 327

Joined: Thu Jan 12, 2006 9:09 pm Location: Plainfield, IL |

[im[img]Woww!!!!!%20%20%20Lots%20of%20work!!!!%20%20I%20have%20gaps%20between%20the%20sheetmetal%20and%20SMC.%20I%20had%20a%20problem%20with%20gaps%20but%20the%20sheet%20metal%20screws%20pulled%20the%20SMC%20flat.%20%20body.http://i272.photobucket.com/albums/jj19 ... ics006.jpg[/img]g][/img

Last edited by Unfettered on Sun Apr 20, 2008 9:48 pm, edited 1 time in total.

"The smoker you play is the drinker you get"

|

Return to Fiberglass and Plastic

Users browsing this forum: No registered users and 27 guests